Packaging for good

Packaging has always had a purpose. Since our early ancestors began to evolve, two things have largely defined the development of civilization—food, along with the ability to store and take it with us. As populations have risen, so has our reliance on lighter, stronger materials like plastic, but with an impact on our natural environment. Packaging is now viewed as a necessity with a cost to the earth, but a look back at how far it’s brought us reminds us that, as long as we find better ways of doing it, packaging can continue to do good for people―and the planet.

In the beginning, we ate food where we found it. But as humans developed farming techniques, wet and dry seasons highlighted the need to store for leaner times. Containers initially produced from nature―like hollow logs or preserved animal skins―gave way to metals, pottery, and glass that better protected food from contamination, damage, or theft.

Once harvested though, food began to spoil, so growth of dangerous pathogens like E. coli had to be slowed―or prevented―by preserving. From as early as 12,000 B.C., communities dried things in the sun or froze them (depending on the appropriate climate) before eventually discovering fermentation, which led to pickling foods in the resulting wines and beers.

The next breakthrough in food safety happened in the 1790s, when French confectioner Nickolas Appert combined packaging and preservation― and discovered that heating food in glass bottles kept it safe to eat. But it wasn’t until Louis Pasteur discovered what caused spoilage and deduced the science behind the process—that microbes already present in food could be killed off by heating— that it became commercially viable. Pasteurization has kept food safe and mobile ever since.

Although still widely used today, pasteurization doesn’t heat products enough to fully sterilize them. Milk, for example, still needs to be refrigerated after it’s pasteurized due to heat-resistant bacteria.

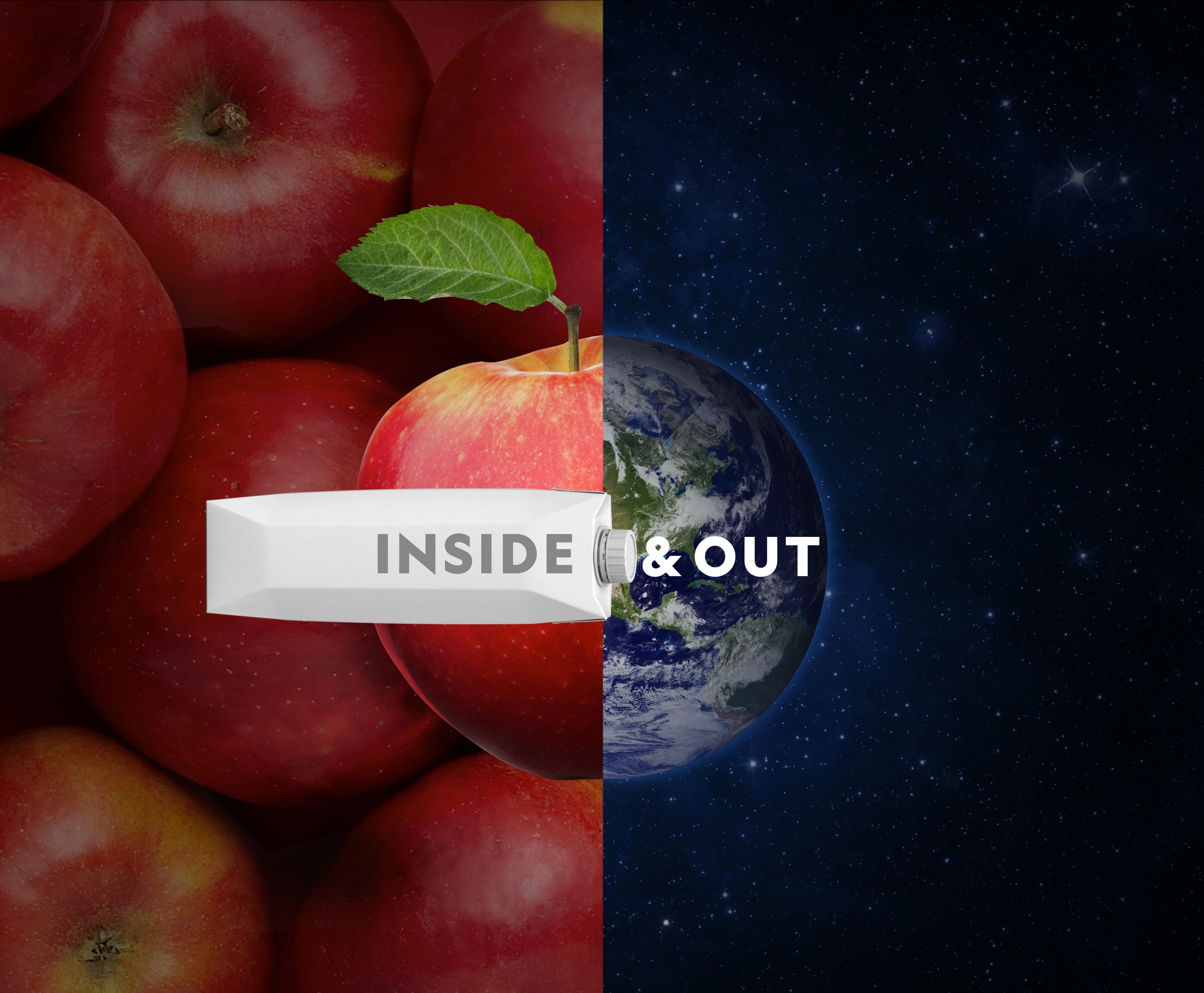

Since the late 1940s, however, aseptic processing and packaging redefined how we’re able to protect food—heating to higher temperatures for less time to sterilize products while retaining nutritional value. Processing and package filling are all kept under sterile conditions until the package is sealed, greatly increasing shelf life without the need for any additional preservatives or refrigeration.

Innovations like this have dramatically improved how we’re able to get food to where it’s needed. In the past two decades, population growth has steadily increased the demand for food, while in developing countries especially, losses during production, processing, and distribution contribute to around a third of all food produced for human consumption worldwide going to waste. This jeopardizes global access to nutrition and makes hunger one of the greatest threats to public health: 25,000 people a day die from starvation and related causes―and nearly half of them are children.

To tackle the issue, the UN Sustainable Development Goals call on governments and businesses to offer aid where they can. National governments fund food assistance, while processing and packaging companies like Tetra Pak help ensure that food is delivered safely. For decades Tetra Pak has made it their mission to address global challenges regarding food safety and availability. Their robust, aseptic packaging means food inside won’t spoil or become contaminated, allowing it to be transported at ambient temperatures to the most remote areas—especially important in developing countries, where lack of refrigeration can make the supply and storage of food problematic.

The SDGs also call for businesses to collaborate with global food development programs, and school feeding programs, especially, to improve children’s health. In 2019, 68 million children in 56 countries received nutritious beverages like milk in Tetra Pak cartons. And to keep kids fed through the Covid-19 pandemic, Tetra Pak has supported distribution, with innovative contactless access to milk through solutions such as automated locker systems.

But getting food products like milk across the world isn’t a completely sustainable solution. It’s better if they’re sourced locally; therefore, Tetra Pak’s Dairy Hub initiative works with smallholder farmers to give them better access to the dairy market.

With the world population likely to hit around 9 billion in the next three decades, we’re probably going to need around 70 percent more food than we currently produce. And, while there’s a way to go yet, history has shown that innovations will help us to not only survive in the future, but thrive as well.

Somewhere around the year 1035, a Persian traveller was perusing a bustling market in Cairo and noticed traders wrapping vegetables and spices in paper for their customers. Outside of China, this was the first recorded use of paper as packaging—flexible, natural, and able to break down when discarded. Nearly 1,000 years later, 6.3 billion metric tons of plastic waste has shown us why it’s a good idea to return to more nature-based packaging solutions.

Packaging has been fundamental to building the food supply chains that support our existence, but this comes at a cost to our planet. Our food system— farming, processing, and distribution—accounts for more than 25 percent of global green-house gas emissions, a number that increases along with the demand for food. Packaging materials help to secure food safety, but some are resource intensive to produce, or won’t break down inside half a century.

While many see recycling as the solution, it isn’t a panacea. It is part of closing the loop on packaging, but it does carry hidden environmental cost. Glass is fragile―which means that the packaging itself needs protection―and it’s heavy, increasing carbon emissions produced in both cleaning and transporting. Aluminum uses so much power to produce that it’s earned the nickname “congealed electricity”—reusing it uses just 5 percent of the energy, but processing still leaves a hefty carbon footprint. Plastic is also mostly recyclable, but it’s estimated that only about 9 percent of all plastic ever made has even been recycled.

So, in addition to recycling, we need a new kind of packaging to take us into the future, and ever more innovative minds are coming up with sustainable solutions. One company tackles both our packaging and our food waste problem by converting crop waste into a plastic-like material using mushrooms, while another technology creates a protective wrapping from potato starch. Innovations like these are in their infancy but, with time, could become valuable contributors to the sustainable future of packaging.

Given its lower impact on nature, paper-based alternatives are appealing to more manufacturers, and Tetra Pak in particular believes that carton packages are one of the best ways to feed our future sustainably. With cartons already comprised of 70 percent paperboard sourced from responsibly managed forests, Tetra Pak plans on increasing the renewable components in its products—including plastic alternatives made from plant-based sources, aspiring toward delivering a carton that is fully renewable, fully recyclable, and carbon neutral.

For Tetra Pak, this future carton has the potential to stabilize the entire food value chain: materials come from renewable sources and responsibly managed forests, low energy usage keeps production carbon neutral, and aseptic processing means products don’t need fleets of carbon-intensive refrigerated trucks to transport. And at the end of the lifecycle? Recycle. Easily and energy efficiently.

Tetra Pak’s ambition supports a global desire to ensure that packaging protects our planet just as well as it’s been protecting food and people—something it’s been doing very well for the last several thousand years.