NASA’s most powerful rocket ever prepares for launch

After years of work, the 322-foot Space Launch System, built to send people to the moon, is finally ready to fly.

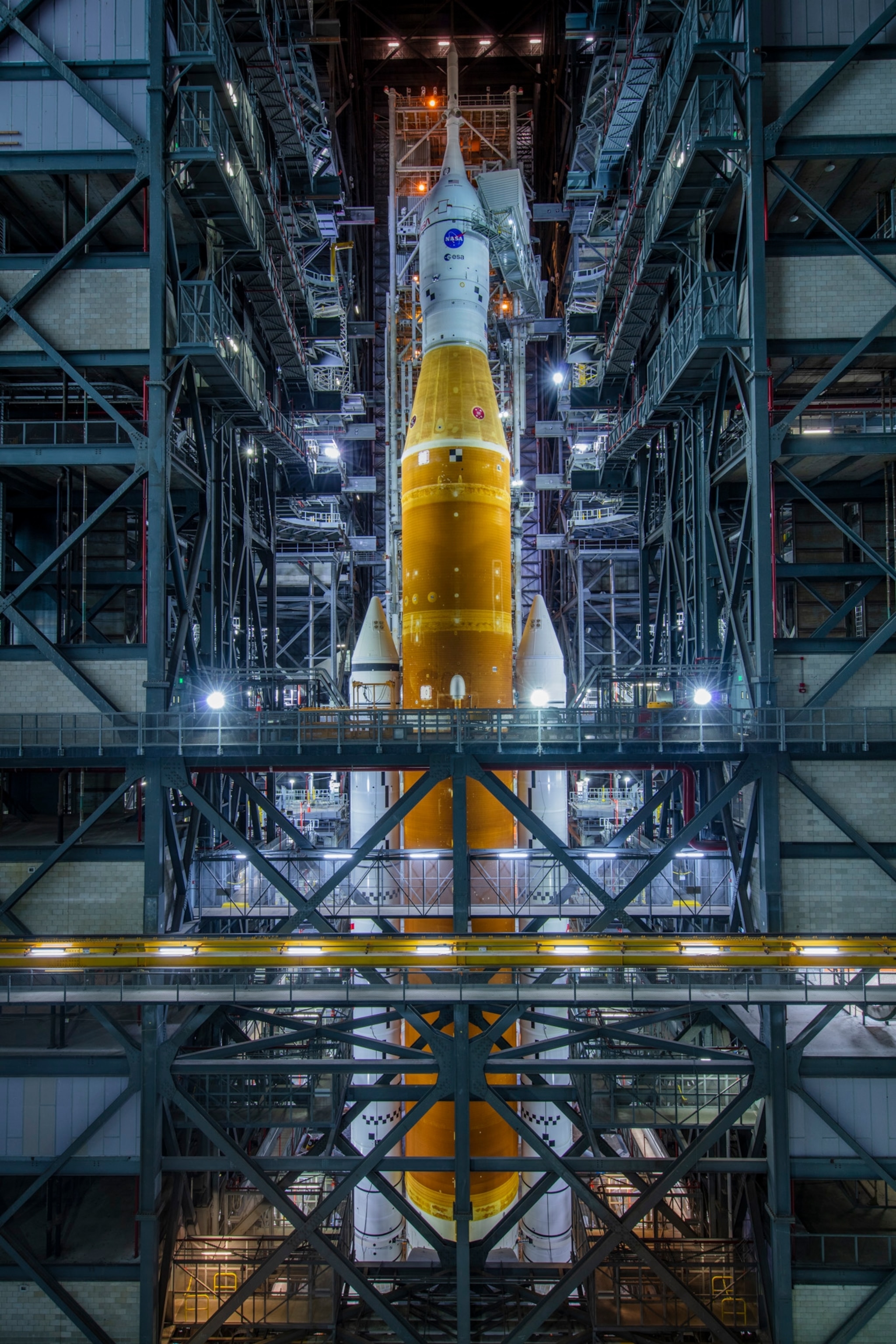

On a cloudless March evening at NASA’s Kennedy Space Center, a 322-foot rocket emerged from the building where it was stitched together. The gigantic orange-and-white vehicle, known as the Space Launch System, was making its public debut, fully assembled for a series of final tests before being cleared to fly. Attached to a support tower and riding on a transport vehicle, it inched toward the launch pad along a 4.2-mile path paved with river rocks. But suddenly, the procession shuddered to a halt.

Was something amiss? Had there been a mechanical issue? The standstill stretched for more than half an hour. As if sensing some mortal flaw in this newly hatched bird, vultures began to circle overhead.

Soon I realized the scavengers were simply riding the hot air rising off the sunbaked roof of the Vehicle Assembly Building, a 576-foot monolith where not only SLS, but the Apollo program’s Saturn V rocket and the winged space shuttle came together. Eventually SLS continued on its way, unperturbed. There were no grim omens—just ways to reach greater heights.

An August 29 launch attempt was scrubbed due to an engine problem, but assuming NASA can resolve the issue quickly, SLS could fly for the first time as soon as September 2 on a mission called Artemis I. This uncrewed test will send a new space capsule called Orion to orbit the moon for between six and 19 days before flying back to Earth.

As soon as May 2024, a crew of four astronauts could fly to lunar orbit on Artemis II—the first time humans will make the roughly 240,000-mile journey since 1972. And as soon as 2025, NASA plans for the Artemis III mission to put people back on the moon.

But before any astronauts can climb aboard, SLS and Orion need to be put through their paces. When Artemis I lifts off, an artificial thunder will roll across Florida’s Merritt Island as four rocket engines and two solid-fuel boosters—the largest ever built—create up to 8.8 million pounds of thrust. In its 500-second climb to space, SLS will hit speeds of 17,400 miles an hour.

The Saturn V was a tortoise off the pad, picking up speed slowly and steadily, while the space shuttle was an eager, jumpy hare. Thanks to its solid-fuel boosters, SLS will probably pop off the pad like the shuttle, leaping skyward on an incandescent billow of exhaust flame.

(See the visual guide on NASA's plan to send us back to the moon.)

The new rocket and Orion capsule are the first human-rated spacecraft designed by NASA since the shuttle, which first flew in 1981. SLS is also the most powerful rocket that NASA has ever built. “I told our team … take a moment,” Artemis I launch director Charlie Blackwell-Thompson said in a briefing days before that first rollout. “Appreciate where you are and appreciate this moment, because being a first doesn’t come along that often in your career.”

To get off the ground, SLS has had to confront more than just the force of gravity. The rocket has faced immense challenges: years of delays, billions in overages, relentless criticism, and the possibility that private companies will soon launch similarly hefty rockets at cheaper prices.

For now, though, SLS is the only rocket capable of launching people to the moon. To John Blevins, the rocket’s chief engineer at NASA since 2019, it represents a fundamental aspect of our species’ unique ambitions. “If you think about societies and how we would describe, like, the Phoenicians, Egyptians, whatever—you describe them generally by their arts, you describe them by their science contributions, and then you describe them by their exploration,” Blevins said. “This is our exploration component for our nation.”

America’s rocket factory

The cores of SLS rockets are born at NASA’s Michoud (pronounced MEE-shoo) Assembly Facility, 15 miles east of downtown New Orleans, Louisiana. This 43-acre plant hosts the bulk of the space agency’s rocket manufacturing. Once a French sugar plantation known for its cypress trees and muskrat population, Michoud got its start in aerospace in 1942 when the U.S. government commandeered an unfinished shipyard to build cargo planes.

In September 1961 NASA took over the facility, eager for a manufacturing site with a deep-water port to build the Apollo program’s Saturn V rocket. The core stage of the Saturn V was made here, as was the space shuttle’s iconic orange fuel tank. “Until recently, you didn’t get out of Earth orbit unless you went through Michoud,” said Boeing engineer Amanda Gertjejansen.

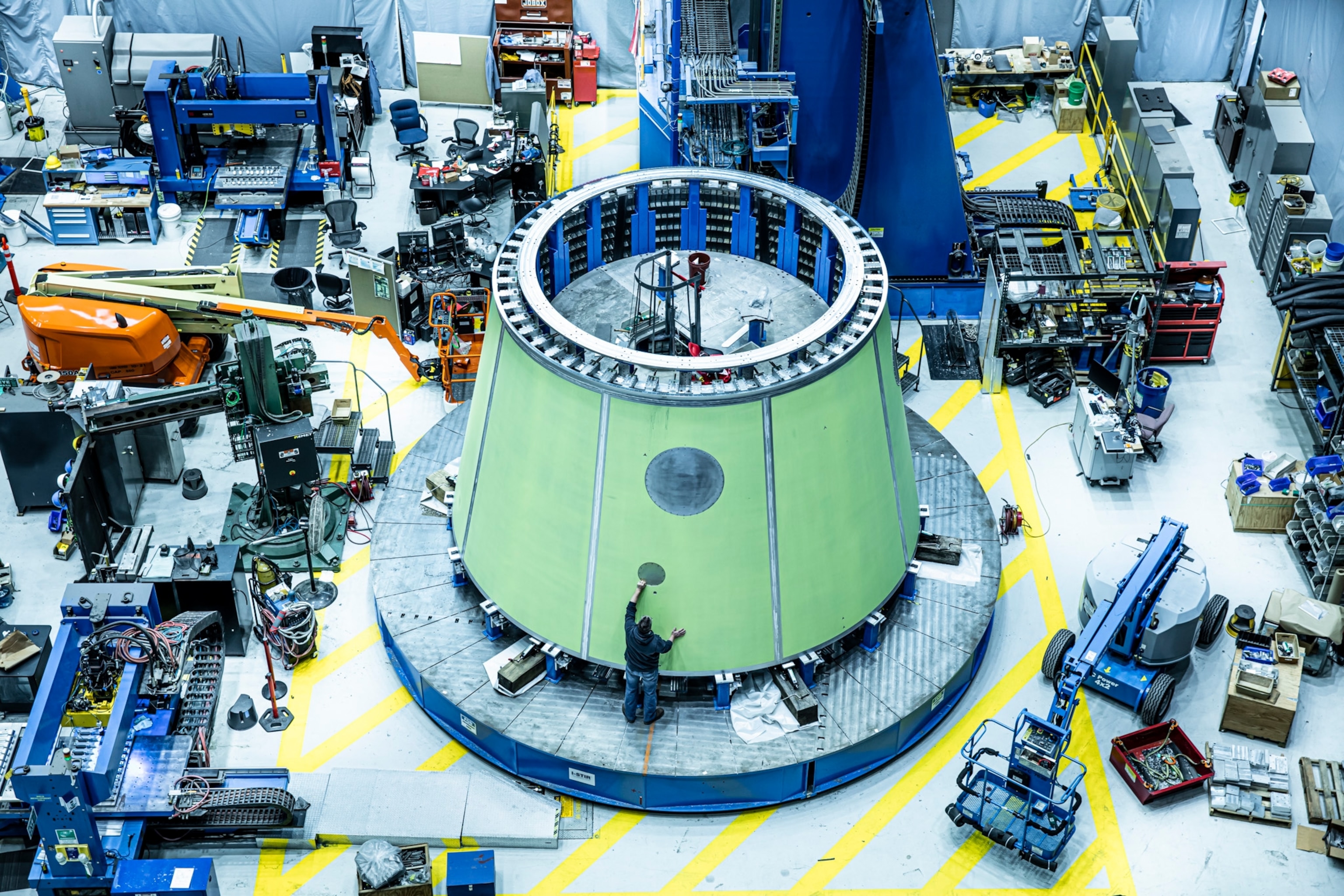

The construction of SLS core stages, overseen by Boeing, moves across Michoud from east to west. Wooden crates stuffed with aluminum panels enter through factory doors. The panels are then welded into cylindrical barrel segments, which get stacked and welded together to make the fuel tanks, intertank barrel, and the cylindrical skirt that connects SLS’s body to the adapters that hold the Orion capsule. After extensively checking welds, spraying foam insulation on the exterior, installing avionics systems, and making innumerable additions and tweaks, finished core stages exit the facility, ready to be floated to Florida by barge.

In another corner of Michoud, Lockheed Martin builds the structural frames for Orion, which are then finished at Kennedy Space Center. The solid rocket boosters that flank the core are built by Northrop Grumman in sections in Utah and then transported by train for assembly in Florida. And the shuttle-era RS-25 engines that power the core stage are tested by Aerojet Rocketdyne in Mississippi.

Building a rocket of this size requires a vast, largely unseen infrastructure. Consider the welds on the SLS core stage. Unlike typical welds made with super-hot torches or plasma arcs, those on SLS are created with friction. A screw-like pin is placed into seams between two metal plates. When spun rapidly, the pin heats up the seam’s metal to about 900 degrees Fahrenheit, just enough to soften it like butter. Dragging the pin along the seam fuses the edges.

The process results in stronger welds with fewer impurities and no need for filler metals. When a test version of SLS’s liquid hydrogen fuel tank was compressed until it burst at more than 2.5 times the loads it will experience during flight, it didn’t rupture along a weld.

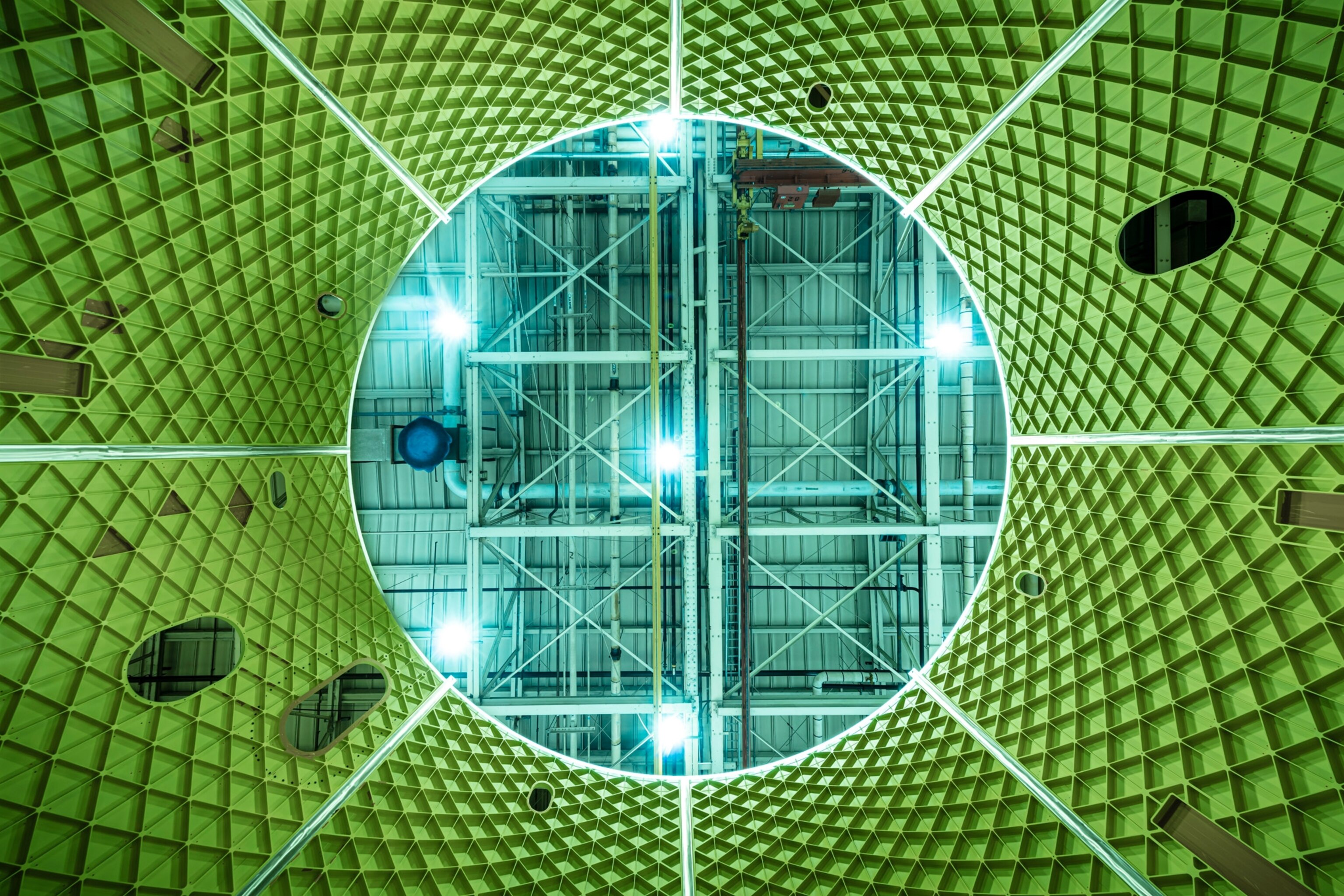

Making these welds requires some serious tools. In Michoud’s Vertical Assembly Center, four pillars of trussed blue steel soar 170 feet toward the faraway ceiling. The 78-foot-wide contraption is the largest welding machine of its kind ever built. Each barrel-shaped segment slots into the tower’s bottom, and with every new segment, the tank grows toward the ceiling. A circle of 72 clamps holds the abutting barrels in place, while a robotic arm runs along a circular track, welding the sections together with the friction pin.

The machine’s foundation contains some six miles of rebar, and filling it with concrete required a line of trucks a mile and a half long. Yet the device is so precise, it can track its own positioning to the nearest thousandth of an inch. Boeing engineer Steve Ernst looked at the tower like a proud parent. “I was one of the original engineers on this one, from the day three of us started sketching it out on a whiteboard,” he told me.

Later that day in Michoud’s Building 103, Gertjejansen showed me the fruit of all this labor: the core stage of SLS for Artemis II. Two hundred and twelve feet long when complete and 27.6 feet in diameter, the vehicle’s core stage felt viscerally, preposterously big: a monument ranging from cream to apricot in color, its foam-covered exterior turning orange as it reacted with oxygen in the air. Thick silvery piping ran along the outside of the rocket to feed the engines with fuel. When we poked our heads into the engine section, which hadn’t been mounted, the cavity had the feel of a cramped jungle gym, stuffed with a thicket of plumbing.

Gertjejansen has seen this rocket come together piece by piece. A New Orleans native, she started with Boeing in Philadelphia; then Michoud came calling for a six-month position. Nine years later, Gertjejansen is responsible for managing a large team of diversely skilled workers. The engine section’s thermal blankets are custom-sewn. The insulating foam is hand-sprayed. The chessboard-like markers along the rocket’s sides—used to track the vehicle’s orientation and speed from afar—are hand-painted. “When you think of building a rocket, you think of rocket scientists, and those are only a very small part of our team,” she said.

Earlier in the day, by the control panels in the Vertical Assembly Center, I met some of the welders. One, a contractor named Shawn McGee, is a third-generation employee at Michoud. His grandmother worked here during Apollo. His father received patents for welding work on the space shuttle.

“It’s really big shoes to fill,” McGee said.

Simulated liftoff

In some respects, SLS is literally borrowing from the space shuttle. Its first four launches will use RS-25 engines that have already flown on shuttle missions, refurbished and outfitted with new flight controllers. Segments of SLS’s solid rocket boosters also flew on shuttle missions, cannibalized from boosters fished out of the Atlantic and refurbished. When Artemis I takes off, components from 83 different shuttle flights will be flying with it.

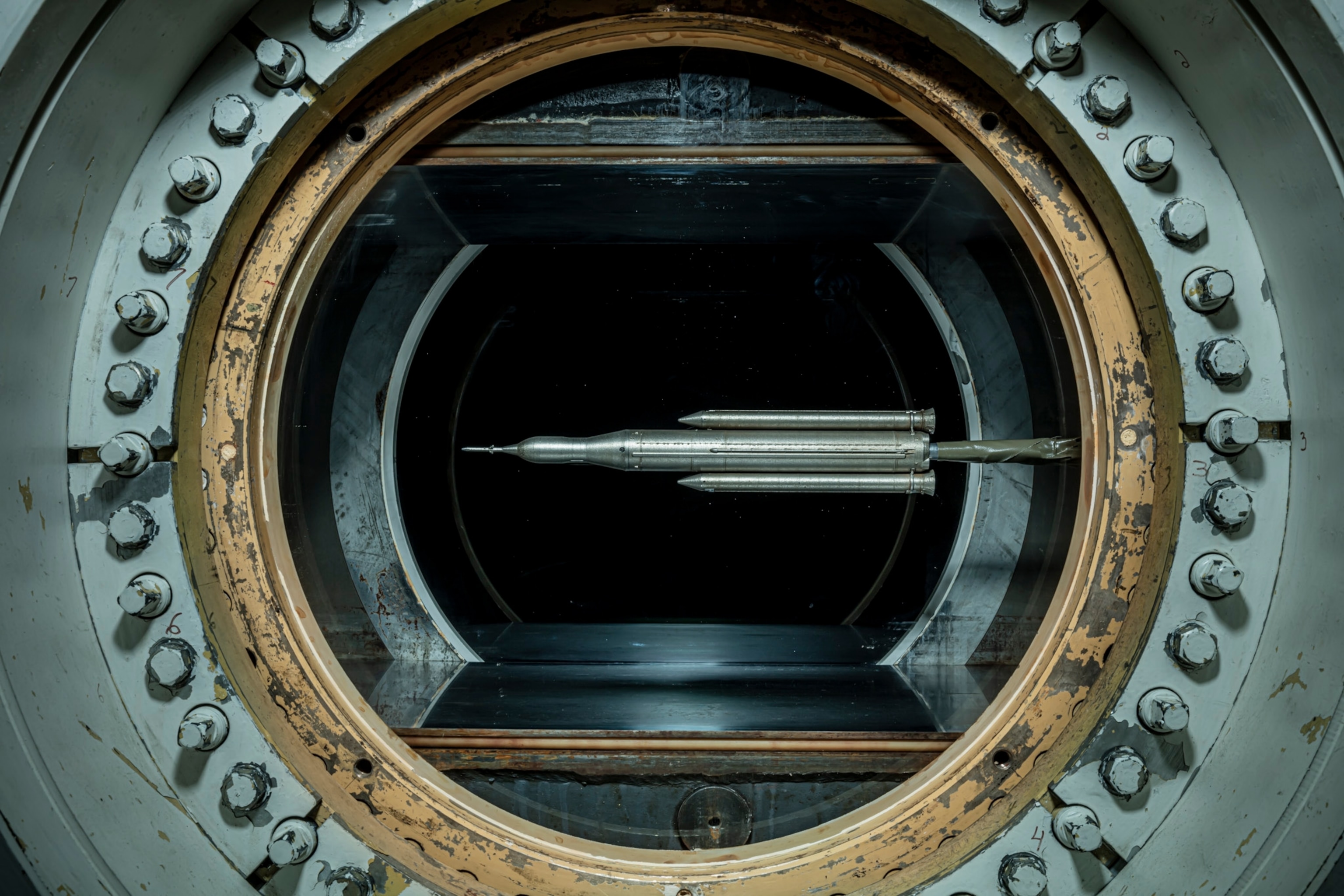

But making a new vehicle out of shuttle-style hardware hasn’t been a cakewalk. The shuttle’s fuel tank sat beside its main engines, but on SLS, those engines are directly beneath the tank—a new environment for tank and engine alike. To study how the new vehicle will behave in flight, engineers use a virtual rocket at NASA’s Marshall Space Flight Center in Alabama.

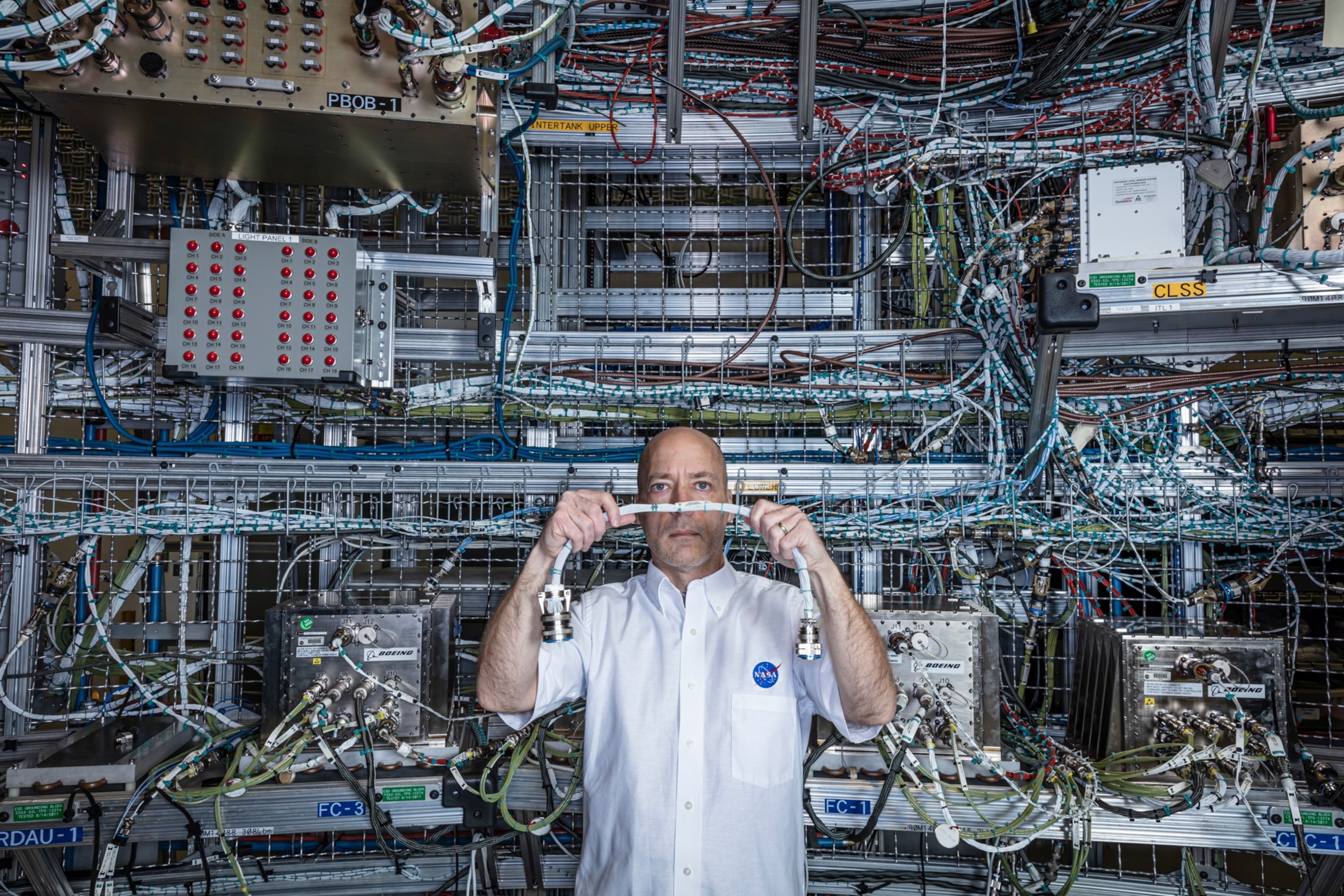

A rack of computers in the Systems Integration Lab, abuzz with fans, traces out a semicircle about as wide as SLS itself. Covered with metallic boxes and bundled white cables, it holds a flight-qualified copy of the SLS computers and avionics. Elsewhere in the lab hums a system called the Advanced Real-Time Environment for Modeling, Integration, and Simulation (ARTEMIS) that simulates SLS launches with exacting precision, down to the propellant in the rocket’s tanks.

Permanently grounded, the computers “get to live a long life, but they have a busy life,” SLS software lead Dan Mitchell said with a chuckle. To the extent that there is a Matrix for SLS, I was looking at it.

ARTEMIS simulates the forces acting on the rocket during launch, from aerodynamic drag to the fuel tanks’ temperature and pressure, up to 10,000 times every second. In response, the SLS flight computer makes adjustments to the virtual rocket once every 20 milliseconds. The flight computer runs a zippy 50,000 lines of code; ARTEMIS, another three million. Together, the system has flown hundreds of thousands of virtual SLS flights, overcoming all sorts of problems thrown at the digital rocket by engineers.

For Shaun Phillips, SLS’s flight software lead, the moment of truth came in March 2021 at NASA’s Stennis Space Center in Mississippi. During a test of the Artemis I core stage, its four RS-25 engines ignited and produced 1.6 million pounds of thrust for a full eight minutes—the amount of time they will need to fire during Artemis I. Until then, the rocket’s software had controlled only virtual rockets for that length of time. Now it was handling the real thing without issue.

“When the engines ignited, it was that heart-beating-out-of-your-chest feeling,” Phillips said. Next time those engines fire for eight minutes, it will be to launch Artemis I to the moon.

Filling the shuttle’s shoes

As is often the case in exploration, the path forward for SLS was hardly a straight one. The rocket’s genesis arguably dates to February 1, 2003, when the space shuttle Columbia broke apart during reentry, killing its seven crew members. By the following January, a review board had called for the shuttles’ retirement, and President George W. Bush had outlined a new plan to send astronauts to the International Space Station (ISS), the moon, and Mars.

This initiative, formalized as the Constellation program in 2005, called for a crew capsule named Orion, a lunar lander, and a family of new rockets. But Constellation soon grew costly and fell behind schedule, and in February 2010, the Obama administration proposed canceling it. The move alarmed Congress, not least because Constellation kept up NASA contracts that support thousands of high-paying, skilled jobs throughout the country.

In response, Congress funded two different rocket programs: the Commercial Crew program that now contracts with SpaceX and Boeing to ferry astronauts to the ISS, as well as SLS.

For the SLS team, the immensity of the task at hand has been compounded by challenges from all directions. A tornado tore past Michoud in 2017 and damaged two buildings, Hurricane Ida ripped into the roof last September, and COVID-19 created setbacks large and small. These external blows added to the countless gremlins and mishaps that plague engineering projects of this size. According to NASA’s Office of the Inspector General, two to three months were lost to a contaminated batch of rocket-fuel tubing. Another nine months vanished when the friction welding machine was misaligned as it was being built.

The rocket is finally ready to fly, but it has come at a price. According to a key NASA timeline from 2014, SLS was projected to cost about $9.1 billion to design and build for a November 2018 launch. This past June, the U.S. Government Accountability Office found that those costs have risen to nearly $11.8 billion, with more than three years of delays.

“It’s been a very frustrating time,” said Lori Garver, who served as NASA’s deputy administrator from 2009 to 2013. “As I left NASA, I said in 2013 I think it would slip a year or two, and at that time it was scheduled for 2017. It has exceeded my worst nightmares—and yet, here we are.”

The issues with SLS are “no fault of the tens of thousands of people who work on this,” she adds. “It’s an accomplishment, even though it has cost so much.”

SLS is not the only piece of Artemis to suffer setbacks. In March, NASA’s Office of the Inspector General estimated that the overall program would cost some $93 billion between October 2011 and September 2025, including $4.1 billion apiece for the first four launches—an “unsustainable” set of expenses, according to Paul Martin, the inspector general.

Critics of the program argue the costs stem from an outdated approach to structuring some of the key Artemis contracts. While NASA owns and operates SLS, it must pay for all expenses that its contractors incur while building it, with extra fees on top. “Artemis as currently designed is the dying gasp of the traditional space industry,” says John Logsdon, a space policy expert and emeritus professor at George Washington University.

The rocket’s builders counter that the program has turned a corner. When construction was first ramping up, a single tank barrel segment took 40 to 50 days to weld together; now, it takes 16. And to hear NASA and Boeing tell it, there’s value in taking the path that SLS has trod. In their view, the rocket is not outdated; it’s proven. Its construction is not plodding; it’s meticulous. Its budget is not excessive; it’s a price worth paying for the future of exploration. “You cannot afford not to do this,” said Chris Cianciola, the SLS deputy manager at NASA Marshall.

To the moon

It will take even more, however, to finish the planned upgrades to SLS. Currently, the rocket has more thrust at liftoff than Apollo’s Saturn V, but it can’t launch nearly as much mass to the moon. In large part, that gap comes down to the rocket’s upper stage, which separates in space and lights its own engines to boost Orion onto a lunar trajectory.

SLS’s upper stage is an interim model with one engine that will fly on only the first three Artemis missions. Starting with Artemis IV, the rocket will use a beefier, four-engine “Exploration Upper Stage” that will increase the mass SLS can launch from 27 tons to at least 38 tons. The rocket will then get upgraded solid-fuel boosters, bringing its lunar payload to more than 43 tons.

NASA will need all this extra capability to construct a space station in lunar orbit, as it plans to do after the Artemis III landing. The space agency also hopes to develop a research station on the moon, using the final configuration of SLS known as “Block 2,” which NASA’s David Beaman, manager of the SLS Engineering & Integration Office, calls the “mother of all vehicles.”

SpaceX, the rocketry company founded by Elon Musk, may disagree with that superlative. In 2018 the company debuted its own heavy-lift rocket, the partially reusable Falcon Heavy, which can launch an estimated 18 to 22 tons to the moon for as low as $97 million. SpaceX also has been building an even bigger rocket called Starship—which, unlike SLS, is designed to be fully reusable. If Starship works, it will enable the launch of large payloads at unprecedentedly low prices. Long-term, SpaceX wants to use this rocket to establish a city on Mars.

Starship is still a prototype, however, and its full potential will only be reached if it can refuel in orbit, which has never been done before. NASA officials stress that there’s no competition, as both rockets are crucial to the success of Artemis. The Artemis III astronauts who land on the moon will leave Earth in an Orion capsule launched by SLS and then transfer to a version of Starship’s upper stage to land on the lunar surface.

The success of Starship also hinges on SpaceX’s ability to land and relaunch the immense rocket. By contrast, each SLS rocket’s days are numbered. Less than two minutes into flight, SLS’s boosters will fall into the Atlantic, and unlike the shuttle boosters, they will not be retrieved. About eight and a half minutes into the journey, its core stage will cut off and break apart as it descends toward the Pacific. And just over two hours into launch, the upper stage will separate from the Orion crew capsule and enter a lonely orbit around the sun.

Gertjejansen strikes a bittersweet tone as she reflects on the fate of each SLS rocket. “You won’t be able to see it forever,” she said, “but you’ll know you were a part of it.”

Before each SLS completes its mission and meets its demise, it must roll down the path at Kennedy Space Center with Orion atop, just as this one did in March.

As the sun set that day, the vultures spiraled into the sky and flew off. The transit vehicle that carried SLS topped out at 0.8 miles an hour as it plodded toward Launch Complex 39B, where the full Artemis I stack would rehearse. On its way, the looming SLS lumbered past throngs of onlookers as the moon came into view above the horizon.

With SLS bathed in lunar light, there was an undeniable beauty in the ambition—the chutzpah—of it all. In a few years’ time, the moon could once again host human visitors, flung there by what amounts to a giant, Creamsicle-colored firecracker.

History will have much to say about SLS and humankind’s next space adventure. For now, for the thousands who brought the rocket to life, the sheer audacity of its voyage will be enough.