Engineering the future: Megastructures for a more sustainable world

Humans have long been obsessed with building big, and as the world strives to combat climate change, megastructures may hold the key to a more sustainable future.

For more than a thousand years, the Lighthouse of Alexandria guided sailing ships safely through the shallows and into the busy harbor of this ancient city. Standing more than 350 feet (110 meters) tall, this marvel of engineering was one of the world’s first megastructures, becoming the model for the lighthouses that are still essential to maritime trade today. Human ingenuity is the cornerstone of civilization. When the world throws people a challenge, we adapt, innovate, and often engineer our way out of the problem. It’s a positivity that lies behind many of the world’s megastructures—and it is what we need to harness if we are to house, feed, power, and move our growing population sustainably.

By 2050, there could be 10 billion people living on the planet, two-thirds of them in cities. Increasingly, urbanization is seen as a positive because cities bring people together, enabling efficiencies in infrastructure and services. The key is controlling their environmental impact by minimizing urban sprawl and maximizing efficiency. For this, planners are gazing upwards to build more sustainable skyscrapers.

At 2,074ft (632 meters) high, the Shanghai Tower’s 128 storeys are occupied by as many as 16,000 people. It is also one of the world’s most sustainably advanced tall buildings. Its design includes a glass outer skin that moderates the building’s temperature and conserves energy, helping reduce its carbon footprint by around 37,500 tons (34,000 metric tonnes) per year. Ingeniously, this outer skin is also curved through 120 degrees to allow the wind to flow around it more efficiently—a twist that reduced the structural steel needed by almost a quarter. Meanwhile, more than 270 integrated wind turbines generate electricity for the building, while smart systems minimize its power consumption. It even harvests rainwater to irrigate numerous sky gardens of plants and trees that help rejuvenate the air of this modern megastructure.

With city dwellers taking up less space, there is more room for nature and farming. And innovative, tech-driven methods could revolutionize agriculture as we strive to feed future populations under the pressure of climate change. One such innovation is vertical farming, where crops are grown indoors in soilless, stacked layers under precisely controlled conditions that increase yield, reduce risk, and enable greens to be grown anywhere—even the desert.

In the United Arab Emirates, Bustanica is one of the world’s largest vertical farms covering 7.6 acres across three floors. With over a million plants being grown at any one time, it harvests more than 6,600 pounds (three metric tonnes) of food every day—and it does this without chemicals. Instead, high-tech hydroponic cultivation delivers nutrient rich water directly to the plant in a closed loop irrigation system that uses just 5 percent of the water needed for traditional farming. Smart monitoring further ensures that light, temperature, nutrients, and all aspects of production are optimized for each crop. The result is risk-free, year-round food production using up to 99 percent less land.

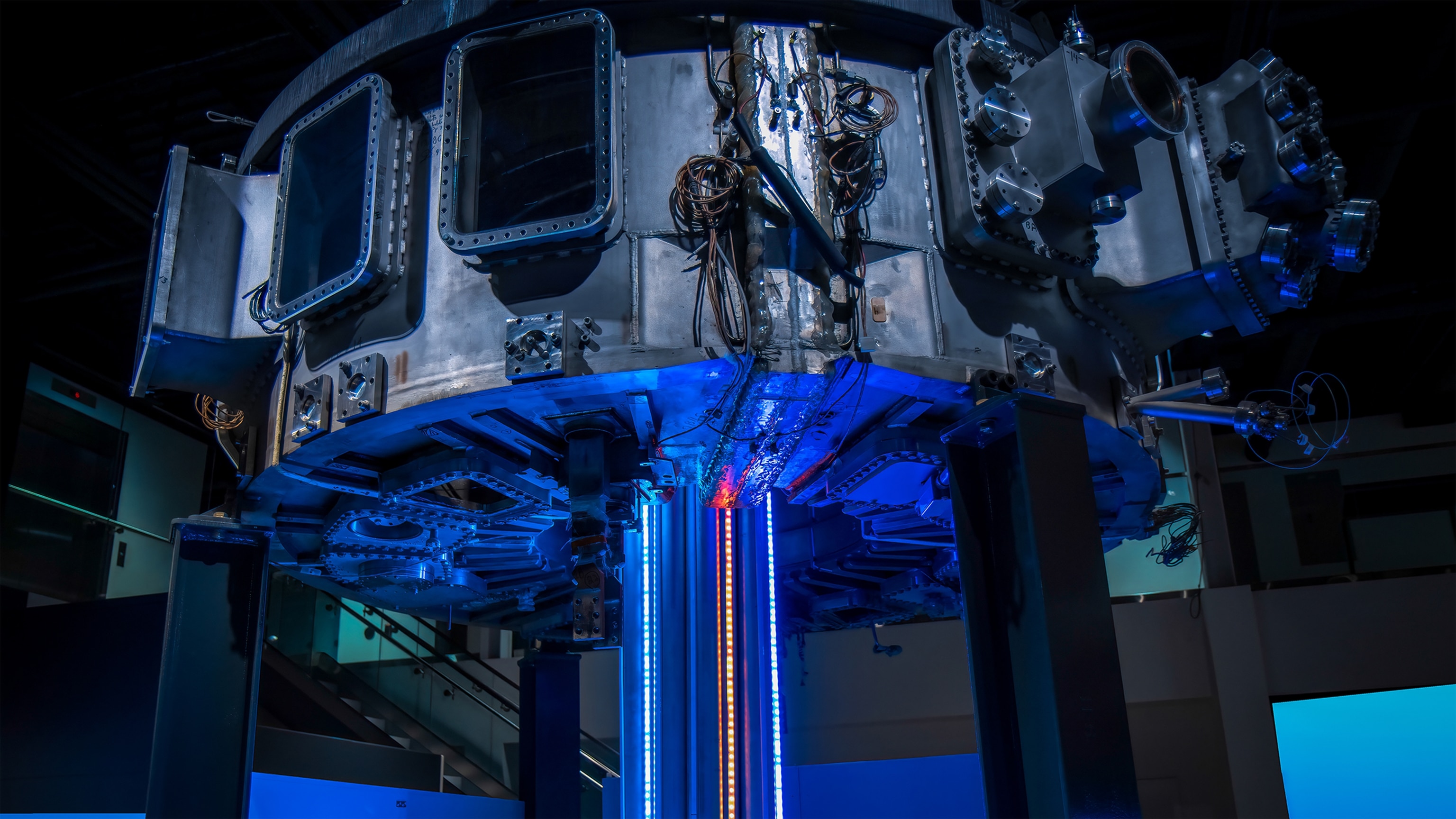

Underpinning our world is electricity, and we are steadily shifting from fossil fuels to renewable energies generated by solar and wind. But scientists are working towards arguably the perfect power source—nuclear fusion. On the sun, hydrogen atoms collide violently and fuse together under immense pressure to release vast amounts of energy. Replicating nuclear fusion on Earth would provide safe, near limitless carbon-free power without the risks associated with nuclear fission.

But achieving this presents one of the biggest technical and technological challenges ever faced, and has involved building the largest and most complex machine of its kind, the ITER tokamak in France. With one million components and 10 million parts, the ITER tokamak aims to demonstrate the feasibility of nuclear fusion by heating hydrogen isotopes to 150 million degrees Celsius. At this temperature and controlled by 10,000 tons of superconducting magnets, they can fuse together and release heat energy to turn steam turbines that generate electricity. With recent fusion breakthroughs generating more energy than was expended, the ITER tokamak megastructure could prove key to delivering this fuel of the future.

And to fuel the world of transport, innovators are taking a fresh look at a technology from the past—wind power. The world relies on moving resources to where they are needed, and shipping by sea remains one of the most efficient methods for long distances—carrying a staggering 14.3 billion tons (13 billion metric tonnes) of cargo each year. To do this, the shipping industry uses more than 220 tons (200 metric tonnes) of oil each year and mindful of its responsibilities is exploring ways to make itself more sustainable with a goal of net zero greenhouse gas emissions by 2050. To achieve this, innovators in Japan are reinventing the age of sail for the 21st century.

Since 2009, Mitsui O.S.K. Lines (MOL) has been exploring the potential of wind power as a clean, unlimited source of propulsion for its vessels. Its Wind Challenger project looked at how modern technology and materials could maximize the deployment of sails on a modern vessel to help push a ship anywhere around 100,000 tons in size across the seas. Keen to ensure that Wind Challenger integrates seamlessly with on board operations, MOL has led its development from the outset—an important commitment from the shipping company to realize the full potential of this innovative new technology. In 2022, MOL’s first Wind Challenger-equipped ship was launched and over three years its sail cut fuel consumption by as much as 17 percent per day—averaging around 5 to 8 percent fuel savings to significantly reduce its carbon footprint. Today, MOL continues to refine the operation and maintenance of each Wind Challenger sail to ensure peak safety and performance.

The Wind Challenger system attaches one or more telescopic masts to new or existing cargo ships. Each mast has multiple tiers of hard sails, each around almost 7,000 square feet (650 square meters) and scientifically shaped to catch more wind. These hard sails are made from a strong, but lightweight composite so as not to upset the balance of the vessel or reduce its cargo capacity. To be able to adapt to the sudden shifts and challenges of crossing the ocean, the deployment of Wind Challenger’s sails is fully automated, being raised and rotated according to the weather conditions analyzed by MOL’s shipboard monitors, enabling Wind Challenger to optimize the available wind or fully retract in bad weather. Further, its high-tech weather routing system optimizes the journey to make the most of winds and currents to further reduce fuel consumption and facilitate MOL’s goal of making Wind Challenger a megastructure for more sustainable transport.

Big isn’t always better, but it can be. Megastructures like skyscrapers, vertical farms, fusion reactors, and modern sailing ships could play a crucial role in overcoming some of the biggest challenges facing our planet. As we seek to innovate our way into a more sustainable future, it’s helpful to think outside of the box—and think big.

More on MOL's Wind Challenger technology here.