Watch Artemis II roll out aboard the heaviest vehicle on Earth

Just moving out the moon-bound rocket to the launch pad was an incredible engineering feat. Watch how NASA got it done.

For the first time since the end of the Apollo program in 1972, humans are returning to the moon. And while they won’t land on the surface, NASA astronauts Reid Wiseman, Victor Glover, Christina Koch, and Canadian astronaut Jeremy Hansen plan to slingshot around the moon on the Artemis II mission this spring. All eyes are on February 6, which is when the launch window opens.

In preparation for the big day, NASA personnel moved the Artemis II rocket to its launch pad this weekend—and it was no easy feat. It involved a complex choreography with some of the most massive machines on Earth.

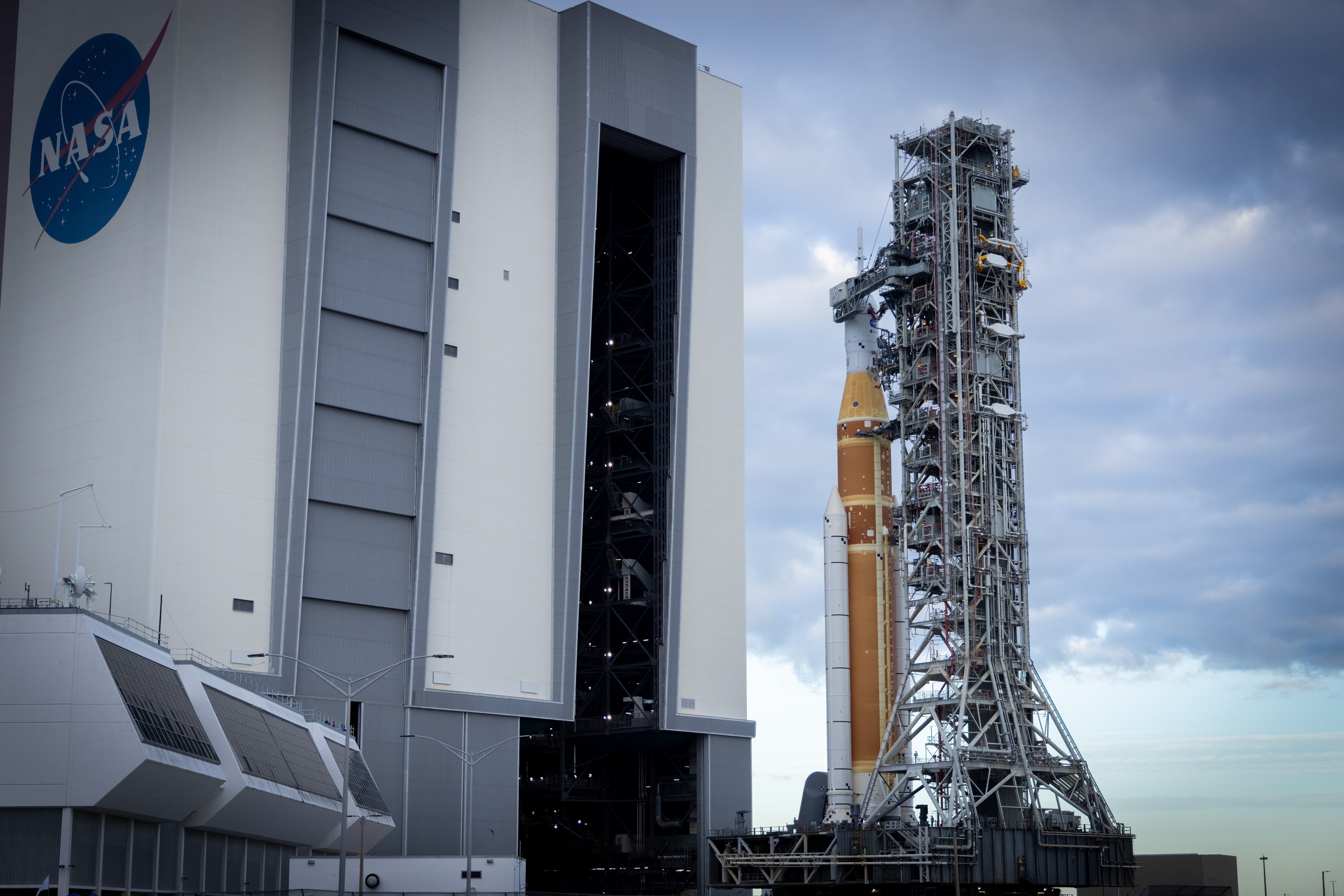

Artemis II consists of the Orion crew capsule—with its launch abort system—nestled on top of the behemoth SLS rocket. All told, it stands 322 feet tall and weighs roughly 3.5 million pounds. Since rocket stacking was completed in October, it has sat in High Bay 3 of NASA’s Vehicle Assembly Building (VAB), one of the largest single-story buildings in the world. The facility is so large by volume, it can hold three-and-a-half Empire State Buildings and was able to stack the SLS rocket vertically.

In this assembly building, the rocket stack was connected to Mobile Launcher 1, the support tower that’s used to assemble the rocket—think of it like high-tech scaffolding for a building under construction. But in this case, it moved with the rocket to the launch pad because it contains, among other important things, the umbilical cables to connect the launch vehicle to power sources.

Completed in 1966, the Vehicle Assembly Building is where the Apollo capsules and Saturn V moon rockets were put together. It’s where the Space Shuttle was mated to its orange external tank and solid rocket boosters. And it’s where scientists and engineers put together Orion and SLS for the upcoming launch.

Artemis II’s core stage was delivered to NASA’s Kennedy Space Center in July 2024. Assembly of the rocket and spacecraft began in November of that year, and stacking was completed in October 2025. And this past weekend, the whole package was delivered to the launch pad, 4.2 miles away.

This in itself was an incredible engineering feat. How do you move something so massive as Artemis II? Enter: Crawler-Transporter 2, the heaviest self-powered vehicle on Earth, which itself weighs a whopping 6.65 million pounds.

Meet the most massive self-powered vehicle on Earth

NASA has two crawler-transporters dating back to the Apollo era, but Artemis presented a new challenge that required updated hardware.

Like the Space Shuttle, SLS carries its mobile launch tower with it, rather than having that infrastructure waiting at the pad. But SLS is much heavier than the Shuttle’s infrastructure. As a result, the combined weight was significantly more than anything the crawler-transporters had ever carried. NASA’s Exploration Ground Services team upgraded Crawler-Transporter 2 (CT-2) to make sure it was up to the job. Completed in 2016, this included engine refurbishments, new generators, new monitoring systems, and redesigning the brakes.

The crawler-transporter is a strange looking piece of equipment. It has massive bulldozer-like wheels flanking a flat platform with nothing on top—that is, until a rocket it placed upon it.

Overall, this machine has the capacity to transport 18 million pounds—which is greater than the weight of 20 fully loaded Boeing 777 airplanes. Artemis II will only weigh about 3.5 million pounds unloaded. The crawler itself added another 11.4 million pounds, for a total of approximately 15 million pounds transported during the rollout.

The fully loaded apparatus was so heavy, NASA had to lay down plywood over the asphalt surface of the assembly building to protect its floor and absorb some of the energy while the rocket was being moved.

The night before: The first milestone

Before rollout, the fully stacked Orion/SLS rocket sat on top of the mobile launcher with 10 platforms providing engineers access to different parts of the rocket and spacecraft. Before rollout began, the team had to move the platforms away.

Then the crawler entered the assembly building through the world’s largest doors. These are 465 feet high, open vertically like massive garage doors, and take 45 minutes to open at full power.

Once inside, the night before the rollout, the EGS team positioned the behemoth transporter directly underneath the mobile launcher with laser alignment. Four pickup points arranged in a 90-foot square (the same size as a baseball diamond) were lined up within a fraction of an inch. Once in place, the crawler used hydraulic cylinders to jack up to within two inches of the mobile launcher’s base, and that’s where the team left things for the night.

The big day: Placing the launch vehicle on the crawler

The morning of rollout started very early. There was a huge checklist for technicians and engineers to complete: from connecting electrical cabling for environmental systems to making sure the crawler’s path out of the assembly building was clear. About one hour before rollout began, the EGS team turned on three of the crawler’s four massive diesel engines.

While the entire system provided 10,000 horsepower across four engines, the goal was to only run three of the engines during any operation.

Once the engines were running, technicians and engineers began the extremely slow process of jacking up the crawler to touch the mobile launcher. The movement is so slow, it’s not visible to the unaided eye. The launch vehicle was then leveled, which is not easy given that the mobile-launcher side of the rocket is significantly heavier its opposite. And then, when Launch Director Charlie Blackwell-Thompson approved of the progress, rollout could begin.

Leaving High Bay 3

Next was one of the most challenging parts of rollout because there were so many potential obstacles. As Artemis II left the security of High Bay 3, it travelled at about 0.05 miles per hour, taking more than 30 minutes just to clear the assembly building doors. Once the rocket was outside, the team paused for another half-hour to rotate the crew access arm around the mobile launcher, retract it, and secure it for the journey ahead. This had to happen outside the building because there’s not enough room inside to allow for rotation.

There were eight drivers certified to drive the crawler, and they operated in hour-long shifts. They all remained on board the crawler-transporter during rollout in a control room, along with engineers and technicians who ensured the security of Artemis II. Four of the drivers had the most experience, and it was these four who were on shift during the most challenging parts of rollout.

The S-turn and beyond

The second challenging point in Artemis II’s journey from the VAB to the launch pad was right outside the assembly building — a tight S-turn that an experienced crawler driver carefully navigated. Shape-wise, it’s similar to a highway on-ramp, but much more precarious (after all, a car isn’t carrying a rocket taller than the Statue of Liberty on top of it).

Once Artemis II was past that S-turn, everyone breathed a sigh of relief. The next six hours were less eventful, as Artemis II crawled towards the launch pad at approximately one mile per hour. The 4.2-mile journey from the assembly to Launch Pad 39B took approximately twelve hours.

Around 2.5 miles before Artemis II arrived at the launch pad, it had to make a sharp left turn. Another experienced crawler driver took the wheel to smoothly guide the vehicle around this bend.

Arrival: Pad 39B

Finally, Artemis II arrived at the launch pad, but still, challenges remained. The last leg of the journey to Pad 39B involved an inclining slope.

The launch pad’s steel-reinforced concrete gently slopes upward, to the actual launch pad which elevated off the ground. Beneath it is a giant, deep trench to catch the flame, smoke, and exhaust the rocket produces during liftoff to avoid damage to the launch pad.

But this also creates trouble in transporting a fully assembled rocket that can’t be tilted while moving up a slanted launch pad. As the crawler-transporter began its slow roll up that incline, computer-powered leveling devices ensured Artemis II was never tilted, and that the crawler-transporter did not stop during the 45-minute journey up the slope.

Finally, once the crawler reached the launch pad, it lowered billions of dollars’ worth of flight hardware precisely onto six mount mechanisms, straddling the flame trench. The team began its checks to make sure that Artemis II was healthy and connected to the electrical supply at the launch pad.

And then? The many people who oversaw the rollout looked upon all they had accomplished.

“Everybody who’s worked on this program is in effect going to the moon,” said Shawn Quinn, program manager for Exploration Ground Systems. “And this rollout is the most visible first step towards getting to that launch.”